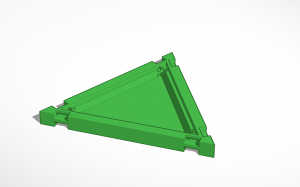

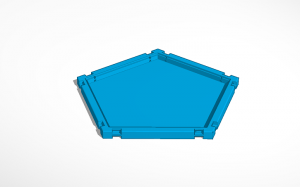

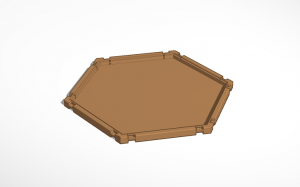

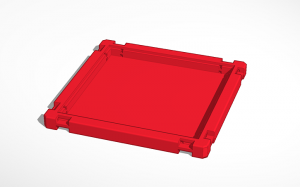

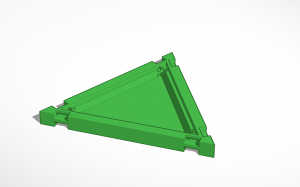

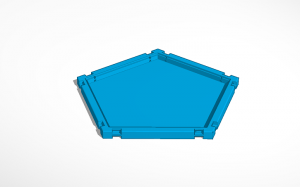

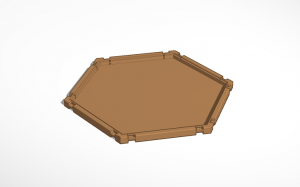

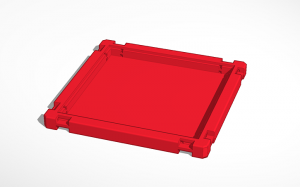

Models prepared to be 3D print based on the design of the first prototype prints

Models prepared to be 3D print based on the design of the first prototype prints

Nicely 3D printed prototypes come with the cavities for the magnets, holes for the wires to the magnets and a rabbet for the front glass.

Thank’s to our friend we have an experienced Blender expert at hand who is more than able and dedicated to visualise lighting objects. Here is a sample of a square tile for lighting purposes, shining it’s lights. A possible problem unveils here that the thickness of the tile may become a challenge. With only 5mm building height material thickness needs to be rather thin. With an estimate 1mm (might be reduced to 0.7mm) thickness for the back of the tile’s case, 1mm for the PCB (might be reduced to 0.5mm with much higher costs) and an assumed thickness of 1mm for an opaque Plexi, there are only 2mm left for LED component height. Thus an even light distribution may become an other incitement.

Five squares made of Forex equipped with the main magnets. Size of 60 x 60 x 5mm seems quite appropriate and handy. They are inviting to play with.

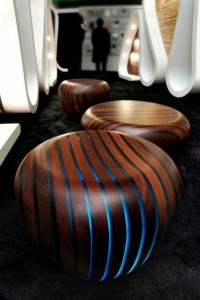

Here is a collection of some very nice luminaries. Got those photo from a friend, thus I don’t know about the creators. However, I want to state, that I didn’t have the ideas nor that I’m the photographer. In this place I want to express my admiration for these project.

Even dwarfes start small!

by Younger Brother